Industry & Manufacturing |

|

|

The speed, precision, and cost benefits of OCT are beginning to attract the interest of industrial end users. For detailed subsurface imaging of small, semiopaque 2D surface areas or 3D structures, OCT is just the thing. OCT’s usefulness for nonbiological applications is less well known, though the technology’s noncontact and noninvasive operating method make it attractive for nondestructive testing and evaluation (NDT, NDE) of manufactured parts. In addition, numerous industrial applications are under investigation, including surface and thickness measurements; NDT, NDE and noncontact material characterization for ceramics, glass and optical components, polymers, fiber composites and paper; and quality evaluation of data storage devices. Additional general information: |

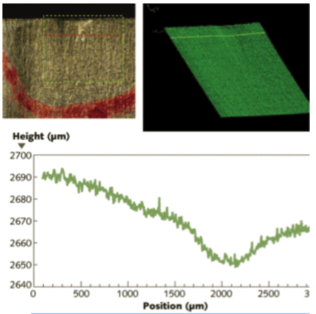

Lines on a photograph (upper left) of a car battery casing |

|

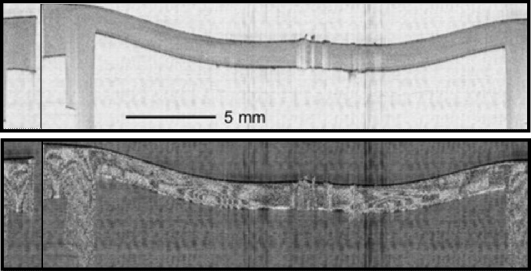

Cross-sectional polarization-sensitive OCT (PS-OCT) image

|

|