How It Works

Development of the All-Semiconductor Laser Technology |

|---|

|

The idea for an all-semiconductor tunable laser was first commercialized in the 1990s and 2000s by Dr. Larry Coldren, co-founder of Agility. Agility spent over $100M developing the technology and and making the technology manufacturable and reliable for demanding telecom applications. These devices must last for 30 years in -35 oC to +70 oC deployments in telecom. Today, hundreds of thousands of lasers based on this technology are shipped per year and are a mainstay of telecommunications systems worldwide. |

Basic Tuning Mechanism of the All-Semiconductor VT-DBR Laser |

|---|

|

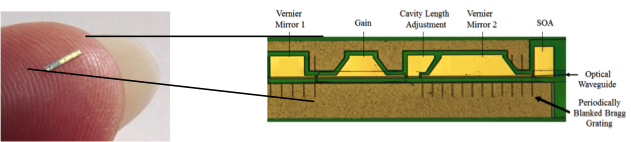

The basic structure of the all semiconductor VT-DBR (Vernier-tuned distributed Bragg reflector) laser is shown below.

|

|

|

|

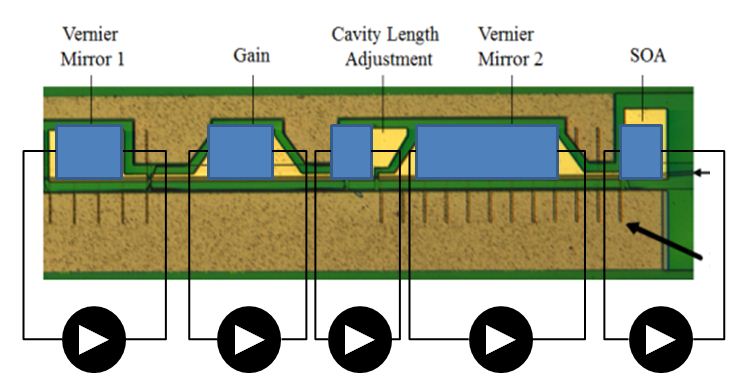

All of these elements are contained on a single semiconductor chip. There are five tuning elements in the laser. Tuning occurs when current is applied to a segment of the laser. This current increases the carrier density in a specific region of the device and changes the index of refraction of the material. This change in the index changes the effective length of that specific segment of the laser. |

|

Two of the segments of the laser are mirror sections (front mirror and back mirror). By applying current and changing the index of the material, the mirror spacing is (effectively) changed. Employing Vernier-tuning effect, these two mirrors can be used in combination to select any wavelength across the tuning band. The phase section of the all-semiconductor laser is very similar to the mirror sections in that the index changes with applied current, but instead of tuning it is used to change the overall cavity length. This is then changed in real time as the laser sweeps to ensure that at every point there is no chance of a mode hop. For many reasons, it is important for the laser to be mode hop-free. Mode hops, or almost instantaneous jumps in wavelength, are a substantial obstacle in obtaining quality images. In addition, the side mode suppression is reduced near mode hops, also resulting in a reduction in image quality. In the VT-DBR, mode hops are avoided by changing the cavity length as the wavelength changes. |

Swept Tuning Technology in the All-Semiconductor Laser |

|

|---|---|

|

In the years since the all-semiconductor laser technology was developed, many groups and individuals around the world have tried to get the laser to sweep linearly over time. Some very capable people have made admirable progress, but none were able to get the laser to sweep linearly over time and temperature to the extent required for OCT imaging applications. We have built on their efforts. |

|

|

|

|

The key obstacle to linear sweeping is the five different current-driven segments to the laser, each of which has an impact on the wavelength of the laser output. Also, the temperature of the laser changes the wavelength substantially, and the laser inherently drifts slightly over time. In addition, there are rise and fall times of the signals and slightly differing lengths for each segment. Compounding this, each of the currents has a direct impact on the wavelength through carrier concentration, but there is also an indirect effect on wavelength through a slight temperature change in the segment. Further compounding this, when the temperature of one segment changes, it will also (with a time constant) change the adjacent segment and then (with a different time constant) change the next adjacent segment (and so on). Every change made also has an effect on all the over variables you control, with differing time constants, and these changes, even change the relationship between the other control variables and the wavelength. An imposing problem, indeed. Insight has spent over 7 years, millions of dollars, and utilized the talents of over 35 development scientists and engineers and 20+ top industry technical advisors (including 15 professors and a Nobel lauriate) to overcome these obstacles. Insight has 14 patents and patents pending, and additional patents in progress. The result is a laser achieving a PSF of 55 to 65 dB; linearity better than 0.001%; 100,000 to 400,000 sweeps per second; and precise output power control. The PSF does not degrade with time or environmental conditions. The laser chip has operated to 1MHz, thus implying additional future improvements. |

|

|

Similar to SG-DBR, tuning is accomplished through index of refraction change in the waveguide without any movement |